Table of Contents

Report

Acknowledgements

Special thanks to Ana Barata for her boundless positive energy and a lot of work.

We also would like to thank all the supervisors and teachers: António Ferreira da Silva, Manuel Santos Silva, Maria Benedita Malheiro, Maria Cristina Ribeiro, Nídia Sá Caetano, Paulo Ferreira, Pedro Barbosa Guedes, Francisco Marques Vieira, Alexandra Ribeiro da Costa, Luis Filipe Caeiro Castanheira and Roger Nylund for their valuable guidance.

To Victor Fernando Ferreira Moreira, Carlos Miguel Silva and António Ferreira da Silva we give our sincere regards for their help in creating our system; their time and patience.

We also thank to Maria Aurora Soares da Silva for helping carrying out chemical tests. We owe a big gratitude to João Francisco Silva for his assistance in solving difficult problems. Thank You all very much.

Abstract

These days water treatment is a very important topic, because the world's fresh water resources are becoming limited. Every year millions of people die from a water related disease and others due to lack of access to clean water. Therefore, our project intends to be a contribution for finding methods for different approaches that will make it possible for already used water to be prepared for a new use.

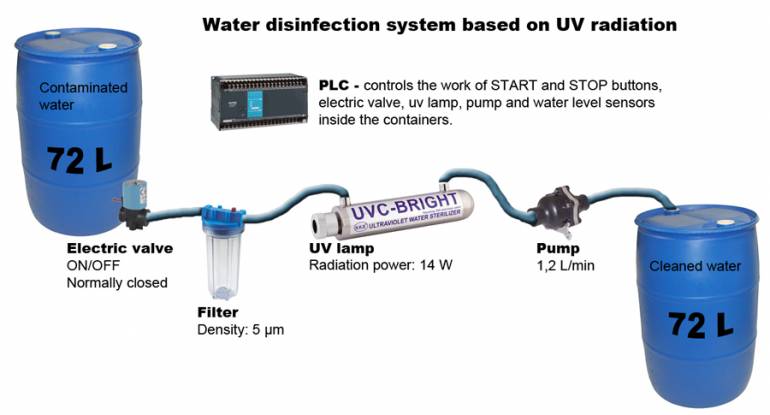

In this report we describe the development process of a system which is going to be applied in contaminated water so that it is disinfected for a specific use: growing algae in an artificial environment. In order to do that, we based our system in UV technology. The whole system is controlled by PLC, and the water in it is filtered and driven by a small diaphragm pump.

The mechanical and control parts of the system were tested and the chemical tests performed afterwards came out with positive results.

Glossary

Water disinfection system based on UV radiation - - Water disinfection with UV (ultraviolet) rays or UV light is a purely physical process and is based on a continuous method (cruising) in the radiant chamber. Microorganisms such as bacteria, viruses, yeasts, etc., subject to the effective UVC rays are irradiated. The cells' DNA or RNA, being activated by photochemical reactions, are inhibited thus inactivating the microorganisms.

UV radiation - Ultraviolet (UV) light is electromagnetic radiation with a wavelength shorter than that of visible light, but longer than X-rays, in the range of 10 nm to 400 nm, and energies from 3 eV to 124 eV ( 1eV = 1.60217646 × 10-19 J).The whole range is divided into 3 types of UV radiation - UVA, UVB and UVC. In our case the developed system is using radiation with a wavelength of 254 nm which is UVC. At this wavelength there is a maximum energy absorption by micro-organisms, which results in bactericidal activity.

Modular system - System composed of independent functional modules.

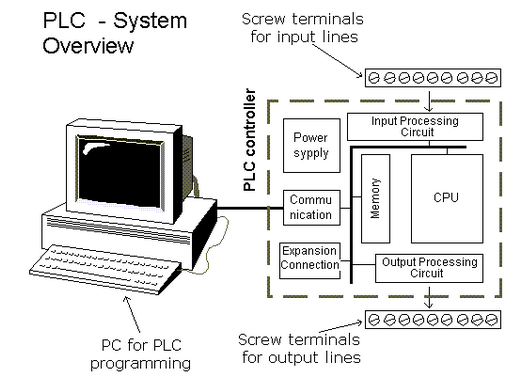

PLC - Programmable Logic Controller or programmable controller is a digital computer used for automation of electromechanical processes, such as control of machinery on factory assembly lines, amusement rides, or light fixtures.

Introduction

The objective of our project is to build and develop a fluid disinfection system which will remove bacteria, viruses and seaweeds using UV radiation. There are several applications and approaches for cleaning the water, like using chemicals (chlorine, ozone), UV lamps, reverse osmosis and filtering. We decided to use UV radiation for removing microorganism, because it is the most advantageous method and fully satisfies our target. Before final disinfection with UV lamp we are using also pre-filtration. The system is controlled by PLC. Our client, who is going to use the system in future research, is the Chemical Engineering Department. We are supposed to design such a system taking into consideration all specifications provided by the client:

- The system must work for 72 l/h with continuous flow-rate

- In the water should not be any viable cells of pathogenic (in particular bacteria, viruses, seaweeds).The cleanness of water should be that sun light can pass through the water and reach about 15 cm depth of water with microalgae

- The system should be controlled by PLC and possess apart from mechanical valve, electrical valve as well

- The budget is 400 €.

To conclude our client`s needs, our goal is to build a system which will be as inexpensive as possible and the most applicable in the future. We intend to use equipment offered by the Chemical Engineering Department and also buy some of them in local stores. The final product will be used at the Insitituto Politécnico do Porto, but it will be universal and can be modified to be adaptable to every laboratory with similar needs.

Our report is divided into six main parts. Firstly, we explain the most important keywords in the glossary and get the reader acquainted with the theoretical background of our project. The following chapter refers to our marketing plan with competitor analysis, SWOT analysis and the marketing program. Subsequently, the sustainability of our system is presented and a detailed list of used materials is included. After that, we briefly present our team and the built system. In the next chapter we describe in detail how our system works and how it was built and programmed. We fully describe every module of our system and also present different solutions regarding water disinfection, which we can be useful in the future. Additionally, we prepared the work plan, considering all tasks and each team member responsibility. To prove that our system works properly we carried out necessary chemical tests and electrical simulations. Finally, we draw some conclusion about our project development, and include some suggestions for future developments.

Apart from some difficulties our team encountered on the way to reach the final result, we eventually managed to build a well-working system which fulfills all the requirements. The biggest obstacle was to find appropriate materials in local stores and sometimes to understand each other within the team. However, thanks to our motivation to work, supervisors’ help and positive attitude we obtained full success.

State of the Art

State of the Art

Nowadays, all over the world, everybody is increasingly seeking different ways how to disinfect and clean the contaminated water in order to use it again. There are several application and approaches for cleaning the water, like using chemicals (chlorine, ozone), UV lamps and filtering. (1)

On the market there are many different systems for purifying contaminated water. Most of them are designed for industrial use. This means that the fluid volumes are very big and these systems take a lot of room and are also expensive. More similar to our idea are systems that have been developed for cleaning the water in pools and ponds. There are the systems that are used in aquariums as well. Our idea is to build a modular system, so every part can be changed easily and different extra devices or equipment can be added if needed, a chemical cleaning/filtering, for instance. The main idea is to build a modular system based on UV radiation because it’s sufficient, fast, environmentally safe and effective (2). And because of the small volumes, our system should be small as well, and compact to fit in laboratories.

Our system differs from the existing solutions in the sense that it is compact, simple, small and modular. Besides that, it’s built according to the needs of our client. In this case the system is also automated, which means that the whole system is controlled by PLC (programmable logic controller). The system has an ON/OFF button, a START button, and water level sensors which will shut off the system if the water level raises or drops to a certain height.

Related Projects and Products

Every project or product developed to treat water is somehow related to our system, because the final goal is to get clean water. Most similar products to ours are the one that also use UV lamps to sterilize the water. Most popular ones are those developed for home use, like this:

Figure 1.Bio-Logic Pure Water Pack ®

Figure 1.Bio-Logic Pure Water Pack ®

These kinds of systems are used in areas where the water from the public water system is not drinkable or people just want to be sure about the quality of their tap water. These systems are really simply built, including two mechanical filters and the UV sterilizer

Conclusion

Water treatment is a very topical issue because of the growing usage of water. There are lots of different ways to clean water. In our system the main component is the UV lamp, which kills all the bacteria. It mainly differs from the other products by its modularity and automation.

Marketing Plan

The name of our company is UniVersal. This name was chosen to reflect the flexibility of the modular system. In the 21st century creating the product is not enough. To sell it, we have to concentrate on the clients, meet their needs, attract their attention and convince them to choose ours instead of other competitors’ product. To do it we have to make several analyses on the market to enter and expand it with ours.

In order to construct and develop our first system and at the same time satisfy our first client we analysed the market respectively:

Current marketing situation

Marketing competitors

Around the world there are plenty of companies that provide fluid disinfection services using UV technology. Those companies are focused on worldwide service in industry and municipal environment. They provide services on an extremely big scale with different applications:

Municipal: drinking water, beverage industry, swimming pool water treatment, Industry: medical, pharmaceutical, industrial wastewater, aquaculture.

Examples of worldwide companies which provide UV technology are the following:

Enaqua

WEDECO

Hanovia

Kurion

Inflico

Aquionics

Each of these companies patented their own UV technology and method of application. Most of them use not only fluid disinfection by UV technology but also other methods like ozone systems or reverse osmosis. They provide plenty of different products for numerous different applications. Those companies are focused on mass production and distribution. They have large budgets and broad teams of specialists and workers.

Competitor advantage

One of the main advantages of our product is being focused only on one specific area: fluid disinfection using germicidal UV lamp. The other advantage of our company service is that it can be the most flexible in the current market. Thanks to the modularity the level of disinfection moves between high rates, we can produce drinking water if this is the client’s need. The idea of our work is not to create our own UV technology but build a system from available equipments on the market and selling the service. All parts can be imposed and ordered by an individual client. Stakeholders have the possibility to choose the best materials and technology depending on their budget and needs. The task of our team is to build such a system for a client and provide the service. We are also targeting more at individual clients like chemical laboratories or small companies. Our clients can always count on our technical support to maintain the system. In comparison to high advanced companies, the price of our service would be low and materials are chosen by clients so they decide on what price they can afford.

Conclusions

To conclude, there are plenty of companies providing UV technology for fluid disinfection and taking into consideration our budget, promotion strategy, used equipment and automation we cannot compete with them. The objective and innovation of our project is to sell our service as flexible as we can for individual clients. We believe that this strategy will be profitable and more attractive on the current market.

SWOT analysis

Strenghts

Materials and equipment can be chosen by individual clients

Project has clear objective and idea how the product and service should look like

We provide modular system which can be adjust to individual client

The product is functional, efficient and has good quality

Great accessibility of the product via our webpage

Long product life time

Weaknesses

Lack of experience

Lack of knowledge in chemical and electrical field

Possible problem with product distribution

Time limitation

Financial and human limitations

Opportunities

Increase market share

Developing and improving the product and service

Recognition at ISEP and other university environments

Looking for new career prospects and challenges

Opportunity of great profit

Threats

Market demand is limited

Big competition on the market

Existence of many similar products on the market

Limitation in product promotion

Possible negative reaction on the market

Evaluating marketing objectives

Costumer segmentation

In the first phase of the project our supplier is ISEP, but if the product will turn out to be successful and efficient we are going to put the product into mass production and distribution. Our future clients might be university laboratories and also smaller domestic laboratories and workshops, more precisely laboratories which are growing different bacteria and want to use the same water after the experiments. Therefore, the main clients are biology and chemical departments in different universities and polytechnic schools. There are approximately 50 of this kind of departments in Portugal. We are also targeting our system at individual clients and small businesses.

Most of the universities are state funded and usually this means that they have tight budgets.

Client needs

Our client most relevant needs are:

- the service and product together should be as cheap as possible;

- quick time of construction and delivery

- it should be modular (to change or add different filters, tanks, equipment);

- easy to use;

- easy to maintain;

- compact – due to the lack of space in laboratories

Market positioning

Our product and service can satisfy all the above points. Even more, we are willing to make any changes to our system and work out new solutions with our clients to meet all their needs. And because the system is easy and simple, it is also reliable.

We differ from other similar companies in flexibility. We are small and we take one project at a time and focus only on that to work out and give the best results to our client.

Marketing objectives

Objective of the company:

- discover the national and in the future worldwide market,

- make research on the market taking into consideration geographic, economic, political aspects,

- enter and expand the market with our products,

- advertise the product,

- design our product according to the needs of the potential clients,

- keep developing our system, make new versions,

- make the service.

Marketing program

When the prototype is finished for the chemical laboratory of ISEP, we will have a working fluid disinfection system, which can clean at least 72 liters of fluid per hour. After that we can sell it on the national market. In order to advertise our product, firstly we have to make a webpage in two languages (English and Portuguese), which introduces our system, describes how it works, tells about the advantages. On this website we would like to emphasize our biggest advantage: the modular system, so it will have a customizing service page where the future clients can get help, more information, and they can contact us personally with special needs via e-mail. We would like to sell our products only on the internet because this distribution way is cheap and we are able to target a big market and we do not have enough money to keep a shop or an office somewhere. So our webpage will have a web shop function, where the clients can buy and customize their product. We will buy position in google. Besides of the internet advertising, we will also participate in fairs, and will print posters. We will offer 2 years of guarantee and full service of maintenance. The clients have to pay for the service after the guarantee is over. There will also be costumer support. At the beginning we will be delivering products by ourselves but if the demand will be higher we will hire logistic company for quicker delivery.

Goals

- Expand the national market

- Develop the system with new ideas

- Personal promotion for the potential clients

- Obtain costumer’s satisfaction

Marketing MIX

About our product

Our product is a fluid disinfection system based on UV radiation system. It will be able to disinfect 72 liters of fluid per hour. The fluid from the first container goes through a filter system and through a spiral involving the UV lamp. Afterwards when it is cleaned the water goes to another container with the help of a pump. The system is controlled by PLC.

Price / cost

In order to set the price we have to firstly estimate the costs of:

- Material,

- Advertising, promotion,

- Packaging,

- Profit,

- Delivery,

- Labour,

- Building

The only price which we know already is 400 € for costs of materials for our first system, but we cannot still estimate exact price of our products, because we do not know marketing and labor costs. What is more, in our case every modular system will have a different price according to the client’s order.

Promotion

We would like to use various types of promotions. We will print posters, leaflet, web advertisement, participate on fairs, visit some potential clients. We also thought about the following slogans: - Invisible but working!

- Working invisible!

- Pure in action!

- Clear by light!

- Let the UV does the dirty job!

We will build a webpage for the product, and pay for the positioning to google, because it is easier for the client, to find us. We will also search some magazines to test and write a critic about our product. The magazines, we think about are the following:

- Ciencia Hoje (http://www.cienciahoje.pt/)

- Science Focus (http://www.sciencefocus.co.uk /)

- Science mag (http://www.sciencemag.org/)

Place of trading

Our field of trading will be the internet, because we don’t have enough money to keep a shop this distribution way is cheap and we are able to target a big market. Our webpage will have a web shop function, where the clients can buy and customize their products. We will also give 2 years of guarantee and 30 days for try. When the product gets popular and we will have enough clients we can open a shop near shopping streets.

Summary

According to the needs we decided to build a fluid disinfection system which is based on the newest and most environmental technology: the UV radiation. The main advantage of our product is the modular system and the cheap maintenance. We are totally flexible to customize the product and adapt new ideas. Our fluid disinfection system has great potential to satisfy the customers.

Eco-eficiency Measures for Sustainibility

Systems which we build are based on the idea of sustainable development which means

THE WAY OF THINKING

YOUR WAY TO SAVE

There are mass-production products which are cheap, as well as more advanced and expensive systems. The availability of so many applications is a challenge for us. Seeking new applications and solutions development is the main objective of our group. Experience and qualifications are our response to your individual and specific needs. Our only competitor is your time and your knowledge, which gives you the opportunity to find better solutions than ours. We provide you an offer based on the following assumptions and actions:

UV technology

The main idea of our systems is the use of UV lamps.

As the water is disinfected by this method it could be re-exposed to biological contamination thus it is possible to apply methods of support. Nevertheless we tried to reduce them to a minimum despite the invaluable advantages of UV technology. It is a safe alternative for dosing sodium hypochlorite for disinfection, or other chemicals. There is no need for storage, transportation and handling of hazardous chemicals. All such devices do not require mechanical cleaning of casing pipes, which greatly simplifies their use and makes it much cheaper. Moreover, this method provides 100% efficiency.

Search your trash

Getting to know your needs and the environment, we seek the best way to use those things you have and do not use often to be administered to our system. We buy only what is necessary to expand your options while thinking about the possibility of these things in the future for other applications.

Modular systems

We build a simple in design and possible to dismantle system. It enables to include additional parts and reuse some of them in other applications. Modules can easily be moved and then put back in place without disturbing any other parts of the system. Our UV lamps can be mounted vertically and horizontally, and at any angle to suit your needs. Installation and removal of our equipment does not require the use of sophisticated equipment.

The whole can be easily assembled (removed) by hand.

Local products

We have studied the local market in search of small and specialized companies with whom we can establish cooperation based on mutual relations. In this way, we are looking for many new and interesting solutions as an alternative way to mass production.

Friendly materials

We discovered local producers and production technologies. We are looking for materials and manufacturing them environmental and people friendly. As the financial capacity to invest in quality materials of known origin. Used for the production of materials and technical solutions guarantee a long and very economical operation of these devices. We believe that the machines are likeable and work on good equipment brings pleasure. From experience we know that people care more about the equipment that they like. This extends its lifetime. In addition, we always choose ergonomics and healthy. All this to make the working environment more pleasant.

It is up to you how much money you destine for your system. Our task is to use them as best as we can.

Energy savings

We focus on water technologies using light that does not require bulky machinery. Expenses incurred for the purchase of the UV sterilizer are recouped very quickly in the form of lower energy costs, which must be supplied with thermal sterilization. Using this method, it also reduces the energy input to operate, transport and maintenance.

Conclusion

We do not offer saving money, but investment in the future. When choosing pay special attention to the safety of our equipment.

Our first system / List of materials

In the following table we present the list of materials

Table2. List of materials

| Product | Provider | Price in euro | Materials |

|---|

| Pump | Peça Filtros | 55,74 | metals and plastics |

| UV system | Peça Filtros | 208,78 | metals, quartz and glass |

| Filter | ISEP | - | plastics |

| Filtrating element | Peça Filtros | 5,07 | fibre |

| Tube | Peça Filtros | 1,2 | plastic |

| Valve | Peça Filtros | 14,76 | metals |

| Opener to the filter | Peça Filtros | 1,84 | plastic |

| Adapters | Peça Filtros | 5,46 | plastic |

| Water level sensors | Peça Filtros | 7,87 | plastic and metal |

| Adapters | Peça Filtros | 4,86 | plastic and metal |

| Platform | António Boiça e Filhos, Lda | 24,21 | wood |

| Small platform | ISEP | - | wood |

| Wheels | Ferragens Zacarias, Lda. | 17,22 | metal and plastics |

| Screws | Ferragens Zacarias, Lda. | 1,57 | metal |

| Screws | ISEP | - | metal |

| Rubers | Carli | 4,40 | plastic |

| Angles | Ferragens Zacarias, Lda. | 6,40 | metal |

| Start and stop buttons | Tupael | 1,48 | plastic and metal |

| Circuit breaker | Tupael | 2,7 | plastic and metal |

| Din rail | Tupael | 1,23 | metal |

| Relays | Tupael | 34,32 | plastics |

| Plugs | Tupael | 9,23 | metals and plastics |

| Wires | ISEP | - | metal and plastic |

| Manual valves | ISEP | - | metal |

| Containers | ISEP | - | composite material |

| PLC | ISEP | - | plastics |

| Power supplier | ISEP | - | plastics |

Total price: 408,34€

In the selection of materials and solutions we are looking for a balance between quality, economy and ecology. Main principle was to use resources which have got a client and reuse them. If possible we choose recyclable and environmentally friendly materials such as wood and metals. If technical considerations require purchasing plastic materials, we always choose those with long lifetime.

Project Development

Introducing the team

Our team has four members, from three countries. Everyone has different educational background:

Joanna Walczak

Country: Poland

University: Technical University of Lodz

Field of study: Biomedical engineering

Main responsibility: Selection of chemical and biological methods

Team role: coordinator and resource investigator

Aleksandra Bazylińska

Country: Poland

University: Wroclaw University of Technology

Field of study: Mechanics and Machine Construction

Main responsibility: The mechanical part of the system

Team role: team worker and implementer

Ádám Jenei

Country: Hungary

University: Obuda University on Budapest

Field of study: Mechanical engineering

Main responsibility: Marketing plan

Team role: finisher and plant

Sander Küttis

Country: Estonia

University: Tallinn University of Applied Sciences

Field of study: Engineering Materials and Marketing

Main responsibility: The electric part of the system

Team role: monitor evaluator and specialist

Work Plan

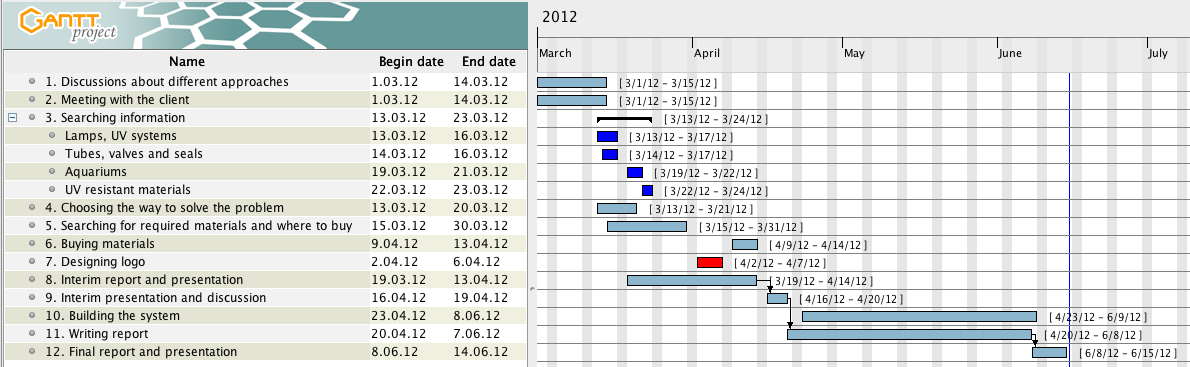

Following table shows how divided the tasks.

Table4. Division of tasks

| Task | Responsible |

|---|

| Search components and materials on the Internet | Joanna, Aleksandra and Sander |

| Gantt Chart | Sander |

| Project sketch | Sander |

| Search for providers and materials in stores | Aleksandra |

| Leaflet | Sander |

| The final choice of materials in stores | Aleksandra, Joanna, Sander and Adam |

| “Competitors” and SWOT part of marketing plan | Joanna |

| Evaluating marketing objectives part of marketing plan | Sander |

| The rest of the marketing plan | Adam |

| Introduction | Joanna |

| State of the Art | Sander |

| Glossary | Aleksandra |

| Team members allocation | Joanna |

| Task allocation and work plan | Aleksandra |

| Eco-eficiency Measures for Sustainibility | Aleksandra |

| Cover | Adam |

| Interim report- structure and graphic | Joanna |

| Mid-term presentation | Joanna |

| PLC | Sander |

| Shopping | Aleksandra,Joanna, Adam and Sander |

| Build the system | Adam, Sander and Aleksandra |

| Final tests | Joanna |

| Logo design | Adam |

| Video and pictures | Adam |

| Functionalities | Aleksandra |

| Paper | Joanna |

| Poster | Adam |

| Final report | Aleksandra |

| Modules | Sander |

| References | Joanna |

| Conclusions | Joanna |

| Abstract | Aleksandra |

| Final presentation | Joanna |

Gantt chart

Architecture

The first product presented on the following figures will be used in Insitituto Politécnico do Porto, but it will be universal and can be modified to be adaptable to every laboratory with similar needs.

Figure 2 presents the idea of a first draft

Figure2. Project sketch

Figure 2 and 3 present the final design.

Figure2. The final product

Figure3. The working part of the structure

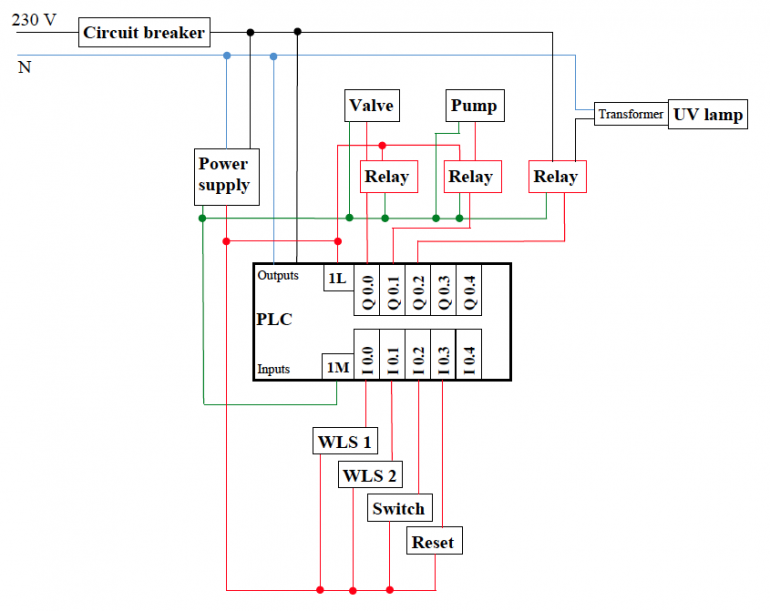

Figure 4 and 5 present the electrical part of the system.

Figure4. Electrical circuit

Figure5. PLC programming

LEGEND:

Inputs:

I0.0 – On/Off button

I0.1 - water level sensor 1

I0.2 - water level sensor 2

I0.3 – Start button

Memories:

M0.0, M0.1

Outputs:

Q0.0 – electrical valve

Q0.1 – pump

Q0.2 – UV lamp

Modules

The Fluid Disinfection System Based on UV Radiation system consists of different kind of mechanical and electrical parts and modules. In this chapter are brought out these modules and their specifications.

UV Water Sterilizer

Specifications:

1. Flow rate: Clean water: 6 l/min,R.O.water:8 l/min 2. Voltage: 220~240 V, 50/60 Hz 3. UV germicidal lamp: 14 W x 1 (Model:UVC-D287T5) 4. Ballast: 14 W x 1(Option: Traditional or Electronic type) 5. Dimension: 64 x 340 mm 6. Inlet / outlet size: 6.35 mm 7. Max. working pressure: 0.86 MPa 8. Chamber/housing: 304 stainless steel 9. Quartz sleeve: Model No. SQ230330 10. Lamp failure warning system: LED + Alarm (option) 11. Lamp, average life: 9 000 h (3)

This UV water sterilizer was chosen taking into consideration the water flow rate of this system. The capacity of the pump is 1,2 l/min, so the capacity of the water sterilizer should be a bit higher to assure that the water is sterilized. On the market, there are also cheaper UV systems available, but this specific sterilizer is more reliable and sustainable because of its stainless steel housing.

Mini diaphragm pump

Pump's task is to pump the water from the first container (contaminated water) through mechanical filter and UV sterilizer to the second container. This pump was selected because of its low throughput so it matches nominal capacity of the filter and UV sterilizer. Higher throughput would have meant higher capacity of other parts and therefore higher price. Mini diaphragm pumps operate using two opposing floating discs with seats that respond to the diaphragm motion. This process results in a quiet and reliable pumping action. Higher efficiency of the pump is evident in the longer life of the motor pump unit. These DC motor diaphragm pumps have excellent self-priming capability and can be run dry without damage, rated to 343.15 K. No metal parts come in contact with materials being pumped. So these mini diaphragm pumps are great chemically resistant. Mini diaphragm pumps prime within seconds of turning the pump on; prime is maintained by two check valves (one on either side). Separated from the motor, the pump body contains no machinery parts, so pump can be in dry running condition for a short while. A built-in pressure switch insides the pump can automatically stop the pump, when the pressure reaches a setting data (4).

Specifications:

1. Open flow: 1.2 l/min 2. Pressure: 0.55 MPa 3. Booster: 24 V DC

PLC

A Programmable Logic Controller (PLC) is an industrial digital computer used for control of electromechanical devices such as control of industrial machinery, pumps, lighting etc. A PLC will be connected to inputs. The PLC processes the inputs in real time based on the logic stored in it and switches the outputs on or off. (5)

In this system PLC is used to control the work of ON/OFF and START buttons (inputs), two water level sensors (inputs), and 3 relays (outputs) behind which the main modules are connected (pump, UV lamp, electric valve). The PLC is programmed like this: first the system is turned on by ON/OFF button which gives the right to the START button to start the system. It means, if pushed, the electric valve is opened and pump and UV light are turned on. The system can be shut down two ways, by the ON/OFF button or by each of the water level sensors. If the system is shut down by the water level sensors, it can be started by pressing again the START button, but only if it's allowed by the water level sensors.

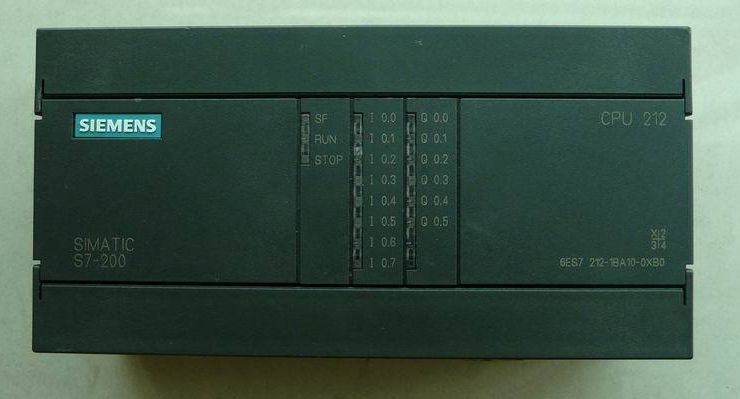

Model No. 6ES7212-1BA10-0XB0, SIMATIC S7-200, CPU 212 (what is used in our system):

Specifications:

1. Size: 160 x 80 x 62 mm 2. Memory: 512 words 3. Local inputs/outputs: 8 DI / 6 DQ

Electrical valve

In this system is used normally closed electrical valve, it is opened only if system works.

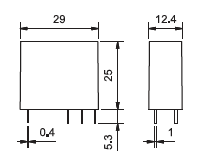

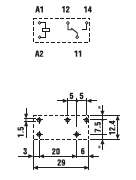

Relays and sockets

A relay is an electrically operated switch. Many relays use an electromagnet to operate a switching mechanism mechanically, but other operating principles are also used. Relays are used where it is necessary to control a circuit by a low-power signal (with complete electrical isolation between control and controlled circuits), or where several circuits must be controlled by one signal. [10]

A relay is an electrically operated switch. Many relays use an electromagnet to operate a switching mechanism mechanically, but other operating principles are also used. Relays are used where it is necessary to control a circuit by a low-power signal (with complete electrical isolation between control and controlled circuits), or where several circuits must be controlled by one signal. (6) In this system relays are used for protecting the outputs of the PLC. If something happens with the UV lamp, pump or electrical valve it breaks down the relay, which is cheap and very easy to replace.

Specifications:

1. Rated current/max peak current: 10/20 A 2. Rated voltage/max switching voltage: 250/400 V AC

Power supply

Power supply is needed to give 24 V DC to PLC outputs, because relays and electric valve and pump are working with 24 V DC.

Specifications:

1. Voltage input: 100 to 240 V AC 2. Frequency: 60 Hz 3. Voltage output: 24 V DC 4. Electric current: 2.1 A

Mechanical filter

In this system filter is placed before the UV lamp to clean the water from any particles which are bigger than 5 μm. It's important for the UV sterilizer so it can work with the highest efficiency. The following figure shows schematically the filter which we used in our system.

Specifications:

1. Pore size: 5 μm 2. Height: 25.4 cm

Functionalities

Water disinfection using ultraviolet

Bactericidal activity is based on the absorption of UV-C light through the structure of the DNA of microorganisms. By using a properly selected time and intensity of UV radiation can completely destroy microorganisms through the destruction of their DNA. Different organisms have different resistance to ultraviolet light. In order to destroy certain microorganisms are given UV dose in mJ/cm2 (6).

The effectiveness of disinfection depends on the microbial contamination of water intended for disinfection. Usually it is defined for indicator bacteria, namely Escherichia coli. For the purpose of drinking water disinfection in waterworks usually taken to be effective for E. coli at the level of 99.9%.This performance provides a UV dose of 40mJ/cm2. The dose is adjusted depending on the application.

UV sterilization lamps are widely used in the world to disinfect water without using heat and chemicals. Disinfection of water in the local scenes, factories, hospitals and laboratories.UV lamps can replace pasteurizers in breweries, mineral water bottling plants, processing plants food, at a fraction of operating costs. These devices provide a sterilizing, disinfecting water in conventional greenhouses and closed loop with drainage. Ultraviolet sterilization in the swimming pools provides chlorination or the abandonment of several dosing reduces the amount of chlorine. Use in ponds and fountains protected from rotting. UV lamps are also used for the destruction of ozone in ozone water.

The main advantages of UV sterilization lamps:

- Devices using UV radiation of wavelength 254 nm damage DNA. This is lethal to microorganisms. The use of proper wavelength protects protein against decay.

- Do not cause any changes in the chemical composition of water,

- You cannot overdose,

- Low operating costs,

- No hassles with chlorine and corrosion,

- Some pathogens such as Cryptosporidium are resistant to chlorination.

Other methods of water treatment

Mechanical filtration

- Partial Filtration- it is the removal of contaminants using filters or filter bed replacement cartridges. The lower limit is 1 µm filtration, - Microfiltrationrange is from 0.05 to 1 µm, - Ultrafiltration– it is characterized by lower speeds of the flow, resulting from a small filtration and it is on special, similar to the osmotic membrane, removable cartridges. Filtration range from 0.01 to 0.1µm.

Carbon filtration

On activated carbon filtration is used to improve the quality of drinking water, especially taste, smell and color. Specially formulated activated carbon stops dissolved in water organic substances origin of humic substances, chlorine and its derivatives, phenols and other substances affecting the taste, odor and color of water. Active carbon filtration should be preceded by mechanical filtration. The simplest method is to use filters with replaceable carbide inserts. These filters can be mounted on the inlet water or at the point, for example, under the sink or the faucet spout. Since the activated carbon can never work as a mechanical filter cartridges because they should contain, in addition specifically of prepared activated carbon, a mechanical pre-filter. Carbon cartridges can be enriched by a factor of KDF (an alloy of copper and zinc in the form of small chips or fibers). It causes a significant reduction of the water of heavy metals, bacteria and free chlorine. Lifetime of contributions depends primarily on the amount of pollutants that are in the water, and the amount of water passed through. To improve the taste and odor, you can apply filters covered with granular activated carbon. Filtration velocity is 15 m / h. The use of activated carbon filters implies a complete removal of chlorine which can cause secondary microbial contamination. This occurs most frequently during water logging. Therefore it is recommended to use a UV lamp and disinfection, replacement cartridges or carbon deposits.

The softening

Water softening is the removal of components causing water hardness. This process involves the conversion of calcium and magnesium ions responsible for hardness of water, the sodium ions. This process occurs in the ion exchangers during the passage of water treated by ion exchange resin. When the bed exchange capacity is exhausted, it is subjected to a process of regeneration with brine. The amount of salt used depends on the quality of the bed and assumed conditions of regeneration. The water treated by ion exchange, while maintaining maximum speed of technological resins, total hardness is below 0.3dH.

Water softeners should be given to be pre-treated by removing the impurities and iron removal, otherwise part of the exchange capacity will be used for the exchange of ions of iron and manganese. Furthermore, as manufacturers provide ion exchange resins, oversize iron lifetime of the resin as much as 50 percent of their projected service life. Therefore, these observations should be considered when designing water softening with a high degree of iron.

Softening is usually one of the elements of water treatment plants for food, heating, cooling and other processes. Water has a very soft hardness to1.78mmol/dm3. Soft water from 1.78 to 3.57mval/dm3, hardcover from 7.13 to 10.7mval/dm3, and very hard over 10.7mval/dm3. The World Health Organization recommends that the overall hardness of drinking water to be contained within the limits of 1-10mval/dm3 (50-500 mg/dm3 CaCO3). The water used for industrial purposes, for cooling or in boiler water and steam also must have certain hardness.

Water hardness is due mainly to the presence of calcium and magnesium ions. Calcium and magnesium ions may be in the form of carbonate Ca (HCO 3) 2, Mg (HCO 3) 2 and then we have carbonate hardness, or in the form of CaCl2, MgCl2, CaSO4, MgSO4, which cause hardness no carbonate. The hardness of which is the sum total of the hardness is removed in strongly acidic Cation Exchangers in the exchange of sodium. Iron and manganese removal

The iron content in groundwater ranges from trace content to tens of mg Fe/dm3. It may appear as: dissolved and colorless or a divalent iron oxidized, precipitated as a red sludge, trivalent iron. Manganese is present in amounts much smaller and usually its contents in the water does not exceed a few mg Mn / dm 3. These elements are dissolved in water in the form of various chemical compounds. The presence of salts of iron and manganese in groundwater causes great inconvenience in the use of water for municipal and industrial purposes and, therefore, in most cases need to operate the water intake and iron removing manganese.

The technological process of removal of iron and manganese consists of:

- Aeration of raw water by means of a compressor or injector

- pH adjustment if necessary

- Filtration using the appropriate fields

Although the salts of iron and manganese are present in the water the same joints (usually as carbonates and sulfates), the removal of their proceeds in a manner somewhat different.

Iron removal

Iron removal is to change the compounds present in water in dissolved iron in insoluble compounds that are retained on the filter bed. A necessary condition to achieve the aeration of water. As a result of aeration of the water is removed with carbon dioxide, so that the increased pH of the water. Iron salts hydrolyze in water is relatively easy to form soluble hydroxides Fe (OH) 2, which are then oxidized by oxygen dissolved in water to insoluble and precipitated iron hydroxides.

Removal of manganese

The complexity of the reactions occurring at demanganization makes the correct and optimal setting of the process requires a high level of service and careful control. You should also pay attention to the interference in the process of manganese, which can cause nitrogen compounds in the water, especially ammonia. In this situation, the oxygen supplied during aeration is consumed for its oxidation, and not for the oxidation of manganese hydroxide. There is then a need to increase the amount of air supplied.

Chlorination of water

Chlorination is the cheapest and most popular way to disinfect. The bacteria are destroyed by acting on the water by chloride or pure chlorine gas. Formation of the hypochlorite - the active compound to disinfect water. The most popular means of disinfection is used for the solution of sodium hypochlorite NaOCl. The dose of chlorine should be selected according to water quality. For the preparation and dosage of the solution are chlorinators.

Chlorinator is composed of: - Diaphragm pump suction-pumping engine - Polyethylene tank sodium hypochlorite solution - Suction pipe in the tank contained a solution of disinfectant - Duct

Chlorinator must be installed in a separate room equipped with ventilation and as close to the receiver, which is to be soda pumped. Side sodium hypochlorite disinfection effect is the deterioration of chlorine odor and taste. Disinfection of water by ozonation.

Ozone consists of passing air through water saturated with ozone O3 (oxygen triatomic). Ozone is produced in special machines called ozone generators. Production of ozone is based on a silent, electric discharge in high voltage alternating field, which affects the flow of clean, dry oxygen or air from the environment. Water ozonation station consists of equipment for the production of ozone (ozonators) and contact tanks for placing disinfected with ozone into the water. The mixing of ozone from the disinfected water in the tank is absorbent (absorber).

As a basic principle widely applicable, the following requirement: to get the highest degree of disinfection of drinking water, the residual ozone concentration of 0.4 mg/dm3 must be maintained for a period of 4 minutes. Ozone has many advantages, which are used in water treatment:

- During the pre-ozonation improves the color and taste of water - Causes the destruction of microorganisms in the water - During the ozone oxidation are essential trace contaminants such as pesticides and surfactants - Ozone causes the biological disintegration of organic substances which, in turn, to a biologically active filter are further broken down to CO2 and water

The disinfection of water by ozonation is most often used for swimming pool water, as well as in the case of objects such as large aquariums. Ozone is also used for wastewater treatment such as surfactants and detergents from the laundry.

Dosing of chemicals Dosing of different types of chemicals to achieve the desired water parameters are used in various industries and at various water treatment technologies such as cooling water treatment, technology, power boilers and air conditioning units, while disinfection of swimming pool and in the technique. Dosing station consists of a diaphragm pump, a solution tank and supply lines . The dosing pump is controlled by an analogue signal 4 - 20 mA, which could be caused for example, the pH probe to the transmitter or by using pulses of water meter contact. Depending on the type of pump is also possible to manually adjust the piston oscillation frequency (change in the number of strokes per unit time) and stroke length (change in volume of fluid dispensed portions during one stroke of the piston).

Decarbonisation The water supply of hot water generators and steam to meet the required standards must be generally subjected to the process of decarbonization. The same applies to water used for cooling purposes. Softening the ion exchanger will exchange the hardness forming compounds readily soluble in neutral salts. Although water is softened, but the overall amount of salt does not change. Sodium bicarbonate (which is formed by replacing the exchanger alkaline carbonate hardness), causing the boiler water or hydroxide caustic soda, which makes it basified. At the same time the boiler is released bound carbon dioxide, resulting in a sour, aggressive condensate and related corrosion damage.

Correction of pH The pH of water is the degree of its acidity or alkalinity and is described quantitatively the concentration of hydrogen ions. The pH of water is a pH indicator. The pH of natural waters usually varies within the limits of 5.5 to 7.5. Neutral solutions have pH = 7, acidic pH <7, and alkaline pH> 7. Water with low pH are characterized by corrosivity, water and high pH have a tendency to foam up.

The pH of water used for food should be in the range from 6.5 to 8.5. The water used for technological purposes such as boiler feed or cooling used also should have the right specified by the manufacturer of pH.

Removal of nitrates from water

Occurrence of nitrate in natural waters is mainly due to the use of nitrogen fertilizers and water pollution due to sewage. Nitrates can be harmful to health. Converted to nitrite, react with amines in the gastrointestinal tract to produce carcinogenic nitrosamines. Removal of nitrates from the water can be carried out by two methods: - Through biological denitrification - Using an ion exchange

Biological denitrification

Denitrifying bacteria are able to convert nitrate to nitrogen gas. Biological denitrification is the introduction of biologically treated water into organic carbon radical, which can be methanol or acetic acid. The amount of the substrate must be strictly defined and controlled, because its excess can make the water unfit for consumption. Biologically treated water anaerobic method may also contain nitrites, and to be contaminated with spores and mycelium in the footsteps of anaerobic microorganisms. Therefore, after nitrogen removal water must be aerated and disinfected by chlorination, ozonation, etc. The mycelium must be removed by flocculation and filtration. Biological denitrification is quite complicated and costly, and is therefore rarely used.

Nitrate removal by ion exchange

Nitrate removal by ion exchange is a comparatively simple process that does not require heavy maintenance. This process occurs in the ion exchangers during the passage of water treated by a special ion exchange resin. Depending on the water content of nitrates, sulfates and chlorides, and their mutual relationship we use the appropriate deposit. Regeneration is carried out with a NaCl solution in a countercurrent system. The amount of salt used depends on the bed and assumed conditions of regeneration.

Residual nitrate content of water treated depends on:

- The type of resin used

- Dose of regenerant

- How to regenerate

Demineralisation

Some processes require a supply of water of very high purity, often completely demineralized. Demineralized water is used among others in the pharmaceutical, cosmetic, food, electronics, energy (water for steam boilers), and also in analytical laboratory, air-conditioning technology, medicine, and everywhere, where local water quality is a prerequisite for proper functioning devices. Demineralization process involves the removal of water of all cations and anions derived from dissolved salts.

This can be done using:

-Reverse osmosis -Ion exchange -Distillation

The choice of method depends on the total salt content (TDS - Total Dissolved Solids) and demand for water. Size used to measure the degree of desalting of water is the electrical conductivity of water, expressed in siemens per centimeter (S / cm). One microsiemens corresponds to 1 million ohms of resistance and is equal to the content of 0.4 mg of salt in 1 liter of water. Equipment for demineralization of water is controlled by measuring the conductivity of treated water. Demineralization by reverse osmosis This method involves the administration of high-pressure raw water (pre-treated) in the semi-permeable membrane which separates two solutions of different concentrations. The molecules of pure water under high pressure passes through the membrane to form the permeate, while the particles of salt and other contaminants such as colloids, bacteria are stopped on the side of the pressure of raw water. Molecules dissolved salts and other impurities are concentrated and are discharged into the sewer. Gaseous constituents of the water (oxygen, carbon dioxide, etc.) pass through the membrane.

The parameters characterizing the reverse osmosis unit:

- Equipment for reverse osmosis differ in the degree of water recovery, - The degree of salt removal, - Equipment included in the RO.

So water recovery rate means the percentage of water flowing to the membrane, which comes from desalinated membrane (permeate). Typically, the water recovery rate is 50-80%. This means that to achieve the productivity of 1 m3/h of water desalinated at a degree of recovery of 75%, you must provide it to the device in an amount of 1.3 m3/h

The degree of salt removal means the percentage of salt removed from the feed water through the membrane. Typical degree of removal of salt for RO membranes is 95-99%.

The degree of salt passage means the percentage of dissolved salts, which passed through the membrane. Desalinated water (permeate) the product obtained in the RO.

Construction equipment for reverse osmosis: The basic element of the device is reverse osmosis RO membrane (semi permeable membrane). Membranes produced today are made from various types of plastics. Membrane and separator are spirally wound on a perforated pipe. Pressure pipe casing forming the membrane can be made of stainless steel or PVC. The water under sufficient pressure to affect the membrane module and is distributed into two streams: desalinated water discharged to the outlet of the central pipe and boiler blow down (concentrate salts and colloids) discharged to the drain (sewer).

Technology “cross flow” used in the membranes (flow of feed water and concentrate parallel to the membrane) uses a pressure that low temperature and low-energy initiates the purification process. Efficiency of reverse osmosis membranes depends on many parameters. These are: pressure, temperature, salt concentration, the degree of water recovery and water reaction. Equipment for RO have the necessary fittings (valves, check valves, solenoid) and instrumentation (pressure gauges, rot meters, conductivity).

Are usually mounted on a steel frame or, for small performance, on a board hanging on the wall. For pumping water into the membrane (raising the pressure of raw water) used high-pressure pump, usually made of bronze or stainless steel. Water treatment technology for reverse osmosis: Preparation of water before giving it to the RO is to delete all the substances that can disrupt or prevent the operation of membranes due to their blocking.

Typical pre-technological line of water for reverse osmosis process is as follows:

First Mechanical filtration Second Iron removal Third Removal of free chlorine 4th Softening 5th Reverse osmosis

Demineralization by ion exchange

Demineralization by ion exchange guarantees the removal of the water almost all the dissolved substances. This method requires extension of the installation of systems for storage and distribution of NaOH and HCl. These compounds are used for recovery of deposits and to neutralize wastewater after regeneration. The particles dispersed in water, salts, acids and bases are dissociated, separated into positively charged cations and negatively charged anions. The process of ion exchange involves the exchange of ions present in water to hydrogen and hydroxide ions, which are on deposit. The cations are exchanged for hydrogen (H +) and anions - the hydroxyl group (OH-). The process is reversible, and the exchange takes place in equivalent amounts. Demineralization by ion exchange can be done in two ways.

Demineralization in the system of two columns

Demineralization takes place in a system of two columns, one of which is filled with strongly acidic cation exchanger working in the hydrogen cycle, the second - a strongly basic anion hydroxide working in the cycle. The cations and anions are exchanged after the other,i.e., the two separated degrees (two columns). After passing a certain amount of water must be subjected to ion exchange bed regeneration. Cation regenerates 6% hydrochloric acid, HCl, which is stored in a tank of acid in the form of a concentrated 33%. The result of acid regeneration are also sewage that are highly acidic with a pH of 1-2, which also contain large amounts of chloride ions. For the regeneration of anion used sodium hydroxide NaOH at a concentration of 4-6%. This rule is stored in tanks of liquor at a concentration of 42%. As a result of the regeneration of waste produced alkaline pH of 11-12.

The mixed bed demineralization

Demineralization takes place in a tank filled with mixed bed, which is a combination of especially gridded ion exchange resins, consisting of strongly acidic cation and strongly alkaline anions. Ratio of cation to anion depends on the chemical composition of the solution. Ion exchange in a mixed bed allows for water quality, which far surpasses the quality of water obtained by distillation or ion exchange on the two columns. When replacing the mixed fluid is removed from the dissolved CO2 and silica. Cation bed, included in a mixed bed is regenerated with hydrochloric acid and anion bed - sodium hydroxide.

Ion grain mixture, by using counter-current rinsing, is separated from regeneration. Because of the difference in weight or heavier appropriate cation exchange bed is at the bottom of the tank and the lighter anion collect seeds on top of the ion exchanger reservoir. After regeneration of the bed is subjected to washing and finally at the end grains are intensively mixed again with water and air(8).

Water treatment methods depending on the impurities present

| Parameters | Methods of water treatment |

|---|

Organoleptic:

| Color | Active carbon filtration / Flocculation + Filtration |

| The pH | Correction of pH |

| Turbidity | Flocculation + Filtration |

| Hardness | Ion exchange / Reverse osmosis |

| Odor | Active carbon filtration / Oxidation / Ozone |

Physico-chemical properties:

| Ammonia | The oxidation / Ion exchange / Reverse osmosis |

| Nitrite | Ozonation / Chlorination |

| Nitrate | Ion exchange / Reverse osmosis |

| Free chlorine | Filtration on active carbon |

| Chlorides | Ion exchange / Reverse osmosis |

| Phosphorus | Reverse osmosis |

| Monophosphates | Reverse osmosis |

| Silica general | Reverse osmosis |

| Manganese | Removal of manganese |

| Magnesium | Ion exchange / Reverse osmosis |

| Potassium | Ion exchange / Reverse osmosis |

| The electrical conductivity | Ion exchange / Reverse osmosis |

| Sodium | Ion exchange / Reverse osmosis |

| Sulfates | Ion exchange / Reverse osmosis |

| Oxidation | Ion exchange / Reverse osmosis |

| Calcium | Ion exchange / Reverse osmosis |

| Organic carbon | Carbon filtration / Ozone + Carbon filtration |

| General iron | Iron removal |

Bacteriological:

| Bacteria, viruses, etc. | Disinfection (Ozone / Chlorination / UV) |

(9)

Tests

First exercise:

Aim of this exercise: The aim of this exercise is to get acquainted with method of bacterial water test and laboratory equipment. Another goal was to check how much tested water is contaminated by bacteria and in result determine amount of this substrate which should be taken to final experience.

Procedure:

1. Prepare mixture of agar to solidify mixture and nutrient to grow bacteria. I used 1.5g of agar and 0.8g of nutrient for 100ml of water.

2. After mixing all together and warming up in microwave to completely dissolve powders in water, I put the mixture into autoclave. There, in condition of high temperature (121 Celsius degrees) and high pressure (2 bar), our mixture and piped tips were sterilized.

3. After sterilization, the next step was to prepare our samples in also sterile environment. We decided to prepare four Petri dishes with: Samples were prepared by incorporation technique.

- 0.25 ml of testing, contaminated water ±20ml of mixture

- 0.50 ml of testing, contaminated water ± 20ml of mixture

- 0.75 ml of testing, contaminated water ± 20ml of mixture

- 1 ml of testing, contaminated water ±20ml of mixture

4. After all I put samples into chamber with temperature of 25 Celsius degrees to solidify the samples and grow microorganisms.

Results and observations:

Results after 24hours: There were easily visible bacterial colonies on each Petri dish. I decided to calculate colonies from: 0.25 ml of tested water and there were 37 colonies and 0.75 ml of tested water where I calculated 211 colonies. I could also easily read out that there were different kinds of bacteria. For example those who likes oxygen (close to cover of Petri dish) and those who doesn`t like oxygen. Results after 3 days: Number of bacterial colonies increased to the amount which is highly difficult to calculate.

Conclusions:

Conclusion from that exercise is that water, which is going to be sterilized in our UV system, is highly contaminated by microorganisms and for the next research is recommended to use 0.5ml of contaminated water and 1ml of disinfected water for the best results and calculations. I can draw also conclusion that in the final examination I should observe my samples after 24hours and 48hours, because after longer time calculating of bacterial colonies is highly difficult and not recommended.

Second exercise:

Aim of this exercise:

The aim of this exercise is to check if our system disinfect the water from all pathogenic cells.

Procedure: 1.Prepare mixture of agar to solidify mixture and nutrient to grow bacteria. I used 1.2g of agar and 0.6 g of nutrient for 75ml of water.

2.After mixing all together and warming up in microwave to completely dissolve powders in water, I put the mixture into sterilization machine like during the first exercise.

3.After sterilization, the next step was to prepare our samples and we decided to prepare two Petri dishes with:

- 0.50 ml of testing, disinfected water ± 20ml of mixture

- 1 ml of testing, disinfected water ± 20ml of mixture

Results after 24hours: There are no visible of bacterial colonies.

Results after 48hours: There are no visible of bacterial colonies.

Conclusions: To conclude, our system disinfected water from all pathogenic cells. Lack of bacterial colonies proves that UV system is proper method to clean delivered by client water.

Electrical simulation

In order to check of our electrical system works we used two useful software: Simulador_S7_200_V2 Esp and MFC PC_Simu version 1.0. Thanks to those software we were able to predict if our programmed logic works properly with PLC and system.

Conclusions

Discussion

Water technology for disinfection, is currently rapid developing field of science. Researches around the world try to find the most efficient way to clean the water for different purposes. Regarding our client requirements our team decided to focus on UV radiation method. UV technology can be used for different applications in science, in laboratories (e.g.: bacterial Identification, medical diagnosis), in industry (e.g.: UV curing), in criminology (e.g.: forensic applications), in electronics (e.g.: quality control) but it is also a big promise to design many innovative systems to clean the water. (10) In our project we proved that UV radiation can be successfully applied to water disinfection and removes pathogenic cells like bacteria and viruses. To sum up our work, we built fully and properly working system and we believe that fulfills all client Page 43 requirements. That proved that method, which we chose and built system, is sufficient in this particular case of water disinfection. The most significant factor that shows value of our project is efficiency of proposed method, and its future application will tell us if proposed idea defend themselves.

During these four months of work we have learnt many different aspects connected with not only mechanical, electrical and chemical knowledge but also teamwork. We improved our cooperation in international team and communication in team. Moreover, we dealt with conflicts and other restrictions and limitations which we encountered on our way. For example: time limitation, budget and knowledge limitation. As we are not specialists in the field of chemistry, electronics and UV disinfection, we had to firstly get knowledge to start thinking how our system should look like. According to electrical part of the system, we were supposed to learn how PLC controller works, how to program PLC and make an electrical stimulation. Regards chemical test, we get acquainted to the method of bacterial water test and laboratory equipment. To sum up, thanks to this project we improved our teamwork skills and get new knowledge which can be useful in our future career.

Future Developments

Current researches are focused on improving water technology for different applications. Many worldwide companies patented their own UV technology and they are using also other methods like ozone systems or reverse osmosis. In our project, we presented and built one main system which is adjusted to our client needs, but also we gave some different possibilities of fluid disinfection using different methods. We can provide service for different individual clients taking into consideration low cost, good quality and sustainability. In the future we can think about building systems for different water treatment applications, like: softening, iron and manganese removal, pH moderation, chlorination of water etc. After getting acquainted with all impose by client parameters and requirements we can modify our UniVersal system.

References

(1) Water.org TM, Available at: http://water.org/water-crisis/water-facts/water/ [Accessed 1990-2012]. (2) Wikipedia, Available at: http://en.wikipedia.org/wiki/Ultraviolet_germicidal_irradiation, [Last uptade: June 2012 ]. (3) Aqua-Win Watertec Co., 2G UV Water Sterilizer, Available at: http://www.aquawin.com.tw/products/uvc-lighting-2G220V.htm, [Accessed from 2008]. (4) Wikipedia, Available at: http://en.wikipedia.org/wiki/Diaphragm_pump, [Last uptade: June 2012 ]. (5) Lakshmi Anand K, Unit 4: Programmable Logic Controller, Available at: [Accessed from 2008]. (6) Wikipedia, Available at: http://en.wikipedia.org/wiki/Relay , [Last uptade: June 2012 ]. (7) Wyczarska-Kokot Joanna - System dezynfekcji wody basenowej wspomagany naświetlaniem promieniami UV, Rynek Instalacyjny 12/2009, Available at: http://www.rynekinstalacyjny.pl/artykul/id1237,system-dezynfekcji-wody-basenowej-wspomagany-naswietlaniem-promieniami-uv. (8) Rosmosis-Wawrzyniak, Available at: http://www.rosmosis.net.pl/main.php?p=oferta, [Accessed from 2007] (9) APECTM, Different water filtration methods explained, Available at: http://www.freedrinkingwater.com/water-education/quality-water-filtration-method.htm [Accessed: 2000 – 2011].